Production at Hay Mills has included the finest music wire, the armour wire for communication cables, spring wire for armaments and locked-coil ropes. These are but a few of the products made there and they have been sold around the globe.

This could not have been achieved without a skilled and dedicated workforce.

In this section we look a little more closely at the Hay Mills works, home to Webster and Horsfall for over 170 years, and most importantly the people who lived and worked there.

The number of employees working at this site has varied over the years; increasing to meet product demand and war work and then falling due to economic recession, declining industries and technological advances.

It has been estimated that the workforce has averaged between 250-300 at many points in its history, but just before World War I, the workforce was at 700. This reduced to 542 in 1916 with many men away fighting. In the last quarter of the twentieth century, numbers were reduced to 275 and currently there are 35 employees.

Working at Hay Mills

In the nineteenth and early twentieth centuries, production processes and sources of power meant that workers often participated in dangerous practices that could result in injury and spent most days in extremely hot and dirty environments. Technological advancements and health, safety and occupational legislation has made working in the wire and wire rope industry much safer.

Long-serving employees would have witnessed production processes changing in line with the latest technology. Wire drawing evolved from an extremely labour intensive manual process to being power-assisted and then mechanised. When making the armour wire for the Atlantic telegraph cable, steam-engine power was used to assist the drawing process; a century later the company possessed seven-hole wire drawing machines.

Similarly, when the Locked-coil rope was developed at Hay Mills, new machinery and tooling had to be designed by Telford Clarence Batchelor and made specially.

Important as the production staff were, the company also employed workers in design and engineering, maintenance, sales, purchasing, administration and management.

Although very much a family business throughout its history, a few key individuals have been recognised with directorships and perhaps the two most notable, were Charles Lean and Frank Luckman.

Charles Lean was the well-respected company secretary for Websters and followed his employer into the Webster and Horsfall partnership. After Baron Dickinson Webster’s death, James Horsfall relied heavily on Charles, who was experienced in dealing with all the administrative matters. Trusted and respected, Charles then became a director and from 1872, much of the day to day running was left in his hands; in fact, the company for a time was called Webster, Horsfall and Lean.

Frank Luckman gave the company 61 years of service and served right up to his death in October 1947. Frank became general manger during Arthur Latch’s time and steered the company through the difficult war periods and the huge production demands that were placed upon the company. Frank’s engineering interest was springs and he steered the company’s production in that direction. His own research into metal fatigue was critical at the time when Webster and Horsfall was the only reliable source of spring wire for the fuses and aircraft engine valve springs needed during the World War I.

The sheer physical nature of the manufacturing work and society’s attitudes to women in the nineteenth and early twentieth century, has meant that the workforce during that time was mostly male. However, following Phoebe Webster, women do have their place in the history of the company. Women answered the call during both world wars, operating machines that were previously only worked by men. Post war, there have been a number of long-serving female employees in purchasing, secretarial and administration roles. Women have held managerial posts and supervised the music wire shop. Towards the end of the twentieth century two female employees also served as directors, recognised for their skill and dedication to the company.

Living at Hay Mills: The Fordrough Cottages

Some workers also lived right next to the works. In about 1860, James Horsfall built a school, a chapel and about two dozen cottages along the Fordrough, from the Coventry road. A small number of those cottages remain today.

At the gala day to celebrate the opening of the school in May 1861, James spoke of how he felt a duty to provide education and religious instruction for those who had been removed from a neighbourhood of schools and churches. He was referring to the workers of Penns, who had no choice but to move to Hay Mills when the Webster operations were relocated there in 1859. At that time Hay Mills was very rural, with a tannery and farms surrounding the works; the workers and their families needed homes.

The census of 1891 records the cottages as Horsfall Croft on Hay Mills Drive but by the 1901 census they are listed as Fordrough. At that time, 16 out of 18 cottages were inhabited; occupied by the works supervisor and a number of wire drawers and wire rope makers and their families. It would appear that retired wire drawers were allowed to live out their days in their home, as Thomas Dunn, aged 83, was the occupier of 7 Fordrough.

Looking at just one cottage in 1891 we find William Wilkens, a wire drawer working and living at Hay Mills. He was born at Penns, which would suggest his father was a wire drawer working for the Websters and relocated after 1859. William was 41 in 1891 and a widower, living there with his mother and 8 children in the cottage. In 1901 he was still employed and living with 6 of his children and by 1911 he shared the cottage with 3 of his daughters and was still working as a wire drawer at the age of 61.

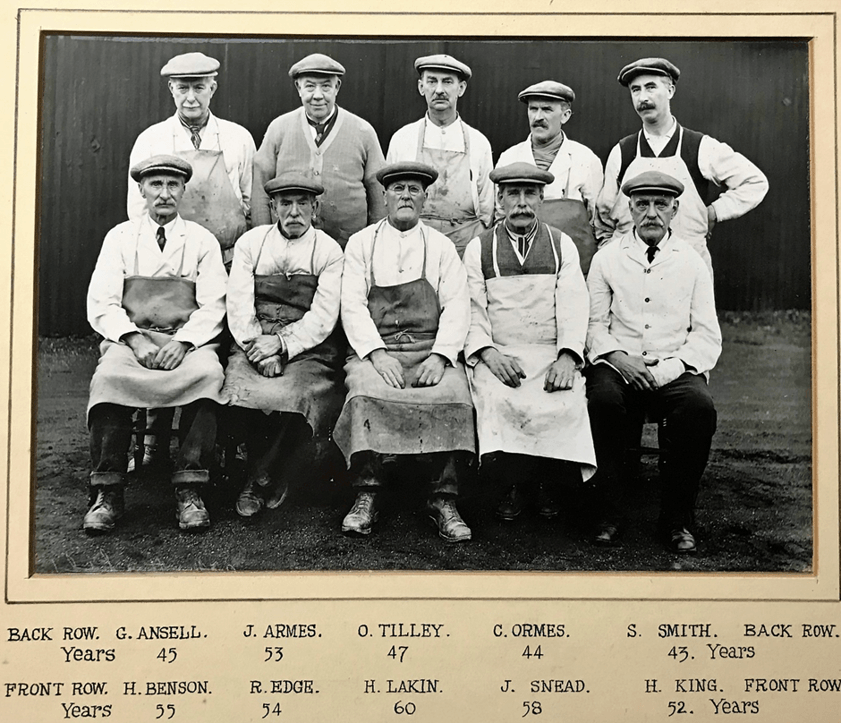

Long service over 40 years was commonplace, it was reputed that 25 years as a wire drawer was considered an apprenticeship. In many cases sons followed their fathers into the trade; J. Armes (in the photograph below) was a fifth-generation wire drawer, his grandfather and great grandfathers all employed by Websters of Penns.

Later, Tommy Simpson, the stoker who looked after the Lancaster boilers, was living in one of the cottages nearest to St. Cyprian’s. This cottage was destroyed by the bomb that damaged the church during the Blitz in World War II. Thankfully, Tommy was not at home, instead out socialising at the Hay Mills Tavern; a sister who lived nearby took him in.

Workers’ Recreation and Sports

Life was not always work and no play. One of the earliest large-scale recreational events at Hay Mills, was that gala day for the opening of the school in 1861. Up to 300 sat down to lunch in a giant marquee and afterwards there was dancing and outdoor games such as football and archery. Celebrations continued the very next day when up to 200 children were entertained at James Horsfall’s expense with tea and a ‘mound of buns’.

Some workers formed the Webster and Horsfall Excelsior Brass Band and they played at James and Elizabeth Horsfall’s 1870 wedding, which took place in the chapel at Hay Mills. The whole works and their families were included in this celebration and up to 600 sat down to dinner, which included a whole roasted sheep with fruits and wine and then afterwards there was outdoor games and dancing. The Excelsior Brass Band was still playing in 1887, providing entertainment at other events, such as the flower shows arranged by local horticultural societies.

Participation in sports was well encouraged with cricket, athletics and football, part of the Birmingham Works Association. There was a sports ground at Hay Mills and team results, division position and match reports were reported in the Sports Argus.

A report from 1949, tells how the Latch & Batchelor football team were having a good season, as they were strong favourites for winning Division III of the Works Association. They were also finalists in the Birmingham City F.C. Shield, to be played at St. Andrew’s. They were also hoping for triple success, competing in the National Wire Masters’ Cup.

The company also held annual sporting events, such as the works cricket match. There was also the Latch & Batchelor A & R.C. Annual Sports Day held at Hay Mills, open to all the community. In the 1930s, the sports day entertained with gymnastic displays, amusements, side shows and refreshments; tickets were 6d or you could pay 1s on the day.

Other local sports associations would also use the facilities at Hay Mills with the Small Heath Harriers holding their Women’s Section Championships there in July 1939, just before the outbreak of war. By the late twentieth century, there was no longer a works sports ground but works teams continued; the cricket team played at a nearby ground.

Socially, workers mostly got together at the local pubs and former women employees remember often meeting up for a girls’ night out and a meal. Others remember Christmas functions held at the works for all employees. In more recent years, past employees remember staff and directors participating in fancy dress for ‘Red Nose Day’ and supporting members of staff completing challenges in aid of charities.

Can you add to the archive?

This brief glimpse has only been possible due to a few retired and long-serving members of staff sharing their memories, and the Trust is keen to gather more memories. One of the aims of the project is to compile a collection of oral histories to enrich the current archive collection.

Were you or a relative employed at the factory? Would you like to share memories or have items of memorabilia that would help tell the story of the workers and community at Hay Mills? The Trust would love to hear from you, please contact [email protected]